The safe side of flash point testing.

eralytics THE NEXT ERA flash point testers are known for their safe, fast and precise measurements and provide a flash point testing solution for every application. The eraflash flash point tester are the future-proof replacement for D93 Pensky-Martens testers using the continuously closed cup flash point standards ASTM D6450, ASTM D7094 and IP 620.

Get your flash point tester that is perfectly tailored to your needs

Whether you’re in the fuel industry, the flavor and fragrance industry, the oil and gas industry or other related industries, we have the perfect flash point solution for you. Get a glance in our eraflash Series Overview Brochure and see all flash point testers at a glance.

eraflash Series Overview Brochure

ASTM D7094 – the future-proof replacemtent for D93

ASTM D7094 flash point testing is the future-proof replacement for ASTM D93 Pensky-Martens testers, bringing 100% safety, unrivalled speed as well as best in class precision to your laboratory. With the wide temperature range of -40 °C to 420 °C (-40 °F to 788 °F) all kinds of liquids can be tested using only 1-2 ml of sample. Take your time and see why PRECISION, SAFETY & SPEED matters.

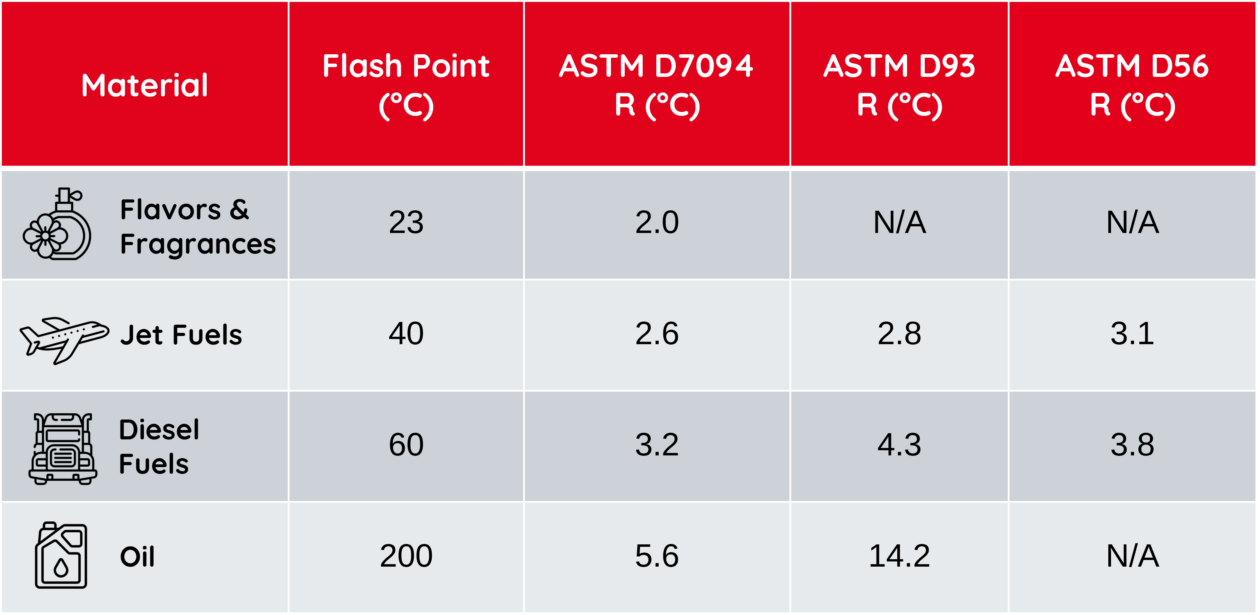

Best in class precision: No bias between ASTM D93 and ASTM D7094

In 2022, the most extensive ILS program of any flash point method to date was carried out with

commercial fuels, involving 20 laboratories and 25 different liquids according to ASTM D6300. These multiple interlaboratory studies (ILSs) have confirmed the exceptional performance of ASTM D7094. It offers outstanding precision across a wide temperature range, even when testing challenging or contaminated samples. Get more on this here:

ASTM D7094 is accepted in the following fuel specifications:

- Fuel oil (ASTM D396)

- Diesel fuel (ASTM D975)

- Gas turbine fuel oil (ASTM D2880)

- Kerosene (ASTM D3699)

- Diesel Fuel, Biodiesel Blend (ASTM D7467)

100% safety with eraflash – The safe side of flash point testing

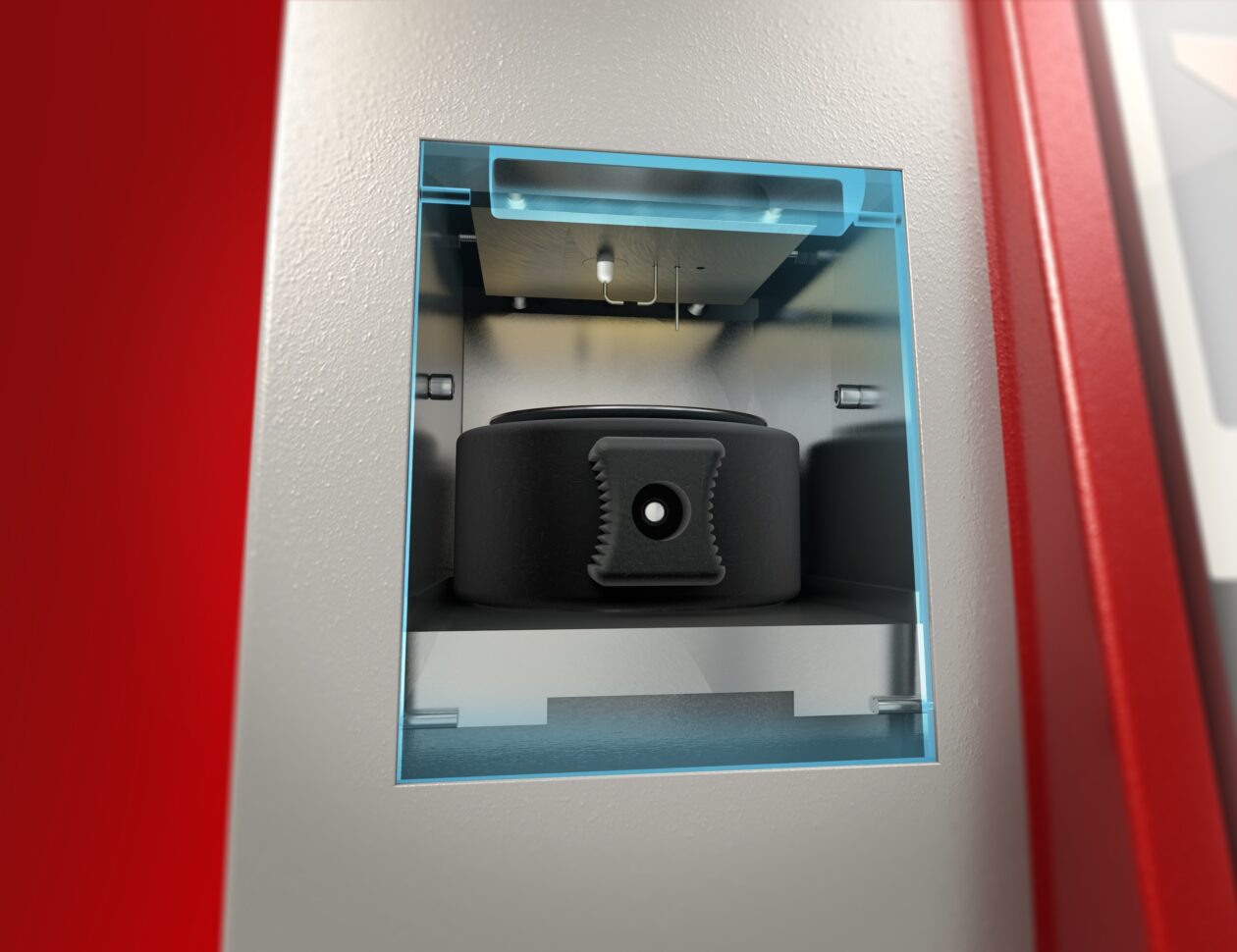

In contrast to Pensky Martens instruments the eraflash flash point tester series does not use an open flame. Instead, 2 pins create an electric arc that is used to ignite the sample inside a continuously closed chamber. Due to the small sample volume (1 ml or 2 ml) and the resulting low oxygen amount within the closed cup, the flame is automatically extinguished after ignition. The pressure increase in the closed cup following the ignition is used for the detection of the flash point. A pressure increase of ≥ 20 kPa is defined as a flash point by the method.

ASTM D6450, D7094 and IP 620 are inherently safe flash point methods eliminating any fire hazard from your lab.

Unrivalled speed: Unmatched heating and cooling rates

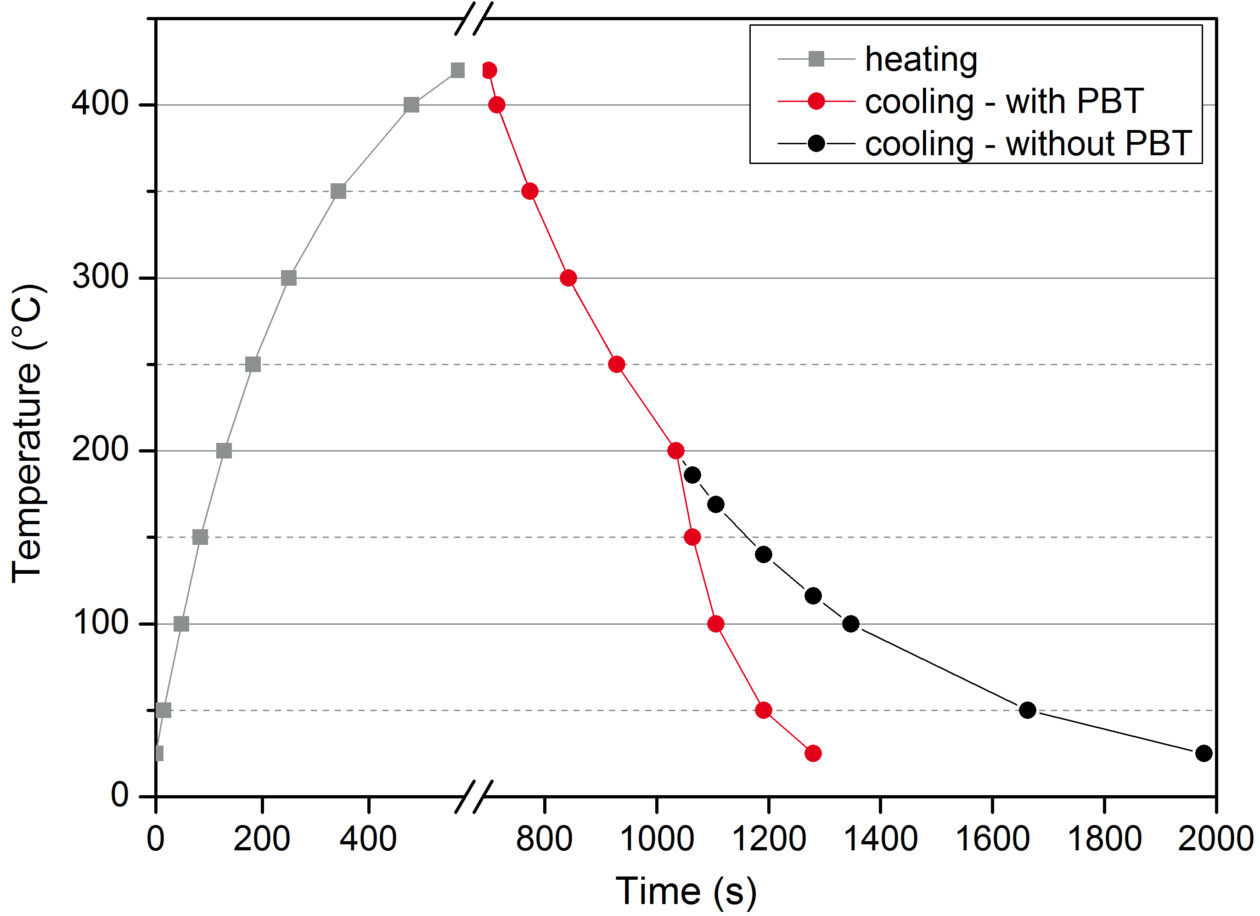

The eraflash point tester utilizes the patented Peltier Boost Technology® (PBT) to significantly increase heating and cooling rates. With a sophisticated mechanism the Peltier elements are safeguarded from high temperatures during heat up and allows their use during cool down even at temperatures that would normally harm them. This eralytics’ innovation maximizes sample throughput by shortening the turnaround time of ERAFLASH.

Additionally PBT enables the eraflash point tester series to cover a temperature range of -25 °C to 420 °C within a single instrument. The new eraflash lt point tester was designed for faster flash point measurements at low temperatures. With its stacked Peltier design it reaches oven temperatures as low as -40 °C.

A reliable partner for critical flash point testing

Designed for robust performance in both laboratory and on-site environments, eraflash delivers reliable results even under harsh conditions. Based on ASTM D7094, its outstanding precision ensures accurate flash point measurements across a wide range of sample types. Trusted by leading organisations, including the US Navy, eraflash has proven itself to be a reliable solution for critical flash point testing worldwide.